Integrating ERP systems is a transformative force in the food industry, where precision, compliance, and efficiency are paramount. These robust software solutions serve as the linchpin for food and beverage businesses, orchestrating a symphony of operations ranging from sourcing raw materials to delivering the final product to consumers’ plates. We delve into the benefits of ERP systems within the food industry. We explore five best practices, common challenges faced, essential features tailored for this sector, and how ERP solutions like Acumatica Cloud ERP empower these businesses to navigate complexities seamlessly.

ERP Systems in the Food Industry

What is an ERP System?

Cloud ERP systems are integrated software solutions designed to manage and streamline core business processes, encompassing finance, supply chain, inventory, production, and sales. Within the food industry, ERP systems play a pivotal role in ensuring compliance, traceability, and efficiency across the value chain.

Application and Benefits of ERP in the Food Business

ERP Best Practices for the Food and Beverage Industry

- End-to-End Traceability: Implement systems that track ingredients from sourcing through production to delivery, ensuring compliance with safety standards.

- Compliance Management: Utilizing ERP modules to meet industry-specific regulations, certifications, and quality control measures.

- Demand Forecasting: Leveraging historical data to forecast demand accurately, optimizing inventory and production schedules.

- Batch and Lot Control: Implementing systems to manage and track batches and lots, aiding in recall management and quality assurance.

- Real-Time Reporting and Analytics: Using ERP tools to generate real-time insights, facilitating informed decision-making across all operational levels.

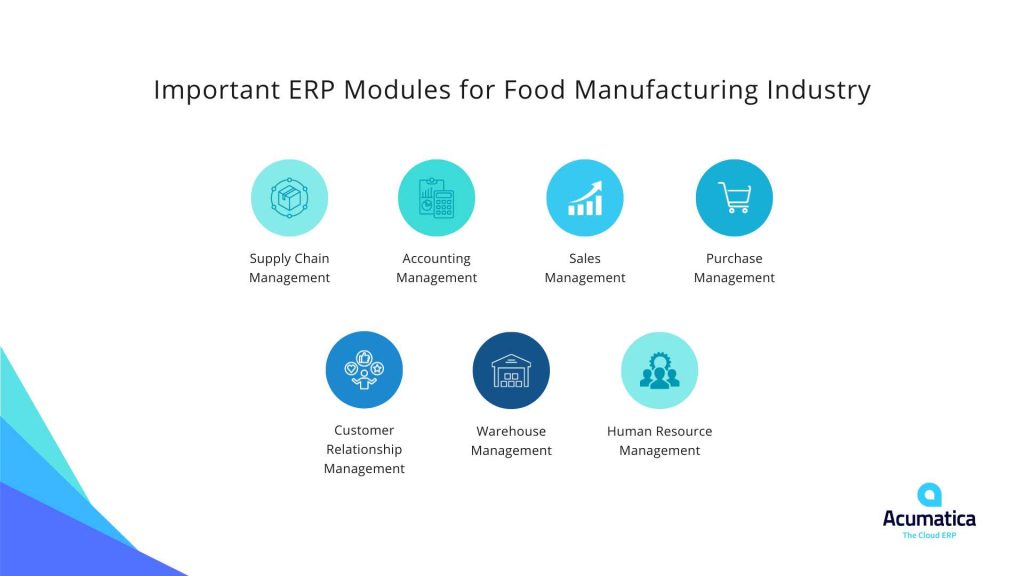

Important ERP Modules for Food Manufacturing Industry

- Supply Chain Management

- Accounting Management

- Sales Management

- Purchase Management

- Customer Relationship Management

- Warehouse Management

- Human Resource Management

Common Challenges That Food and Beverage Companies Face

- Complex Supply Chain: Managing perishable goods, multiple suppliers, and compliance across various stages.

- Stringent Regulatory Requirements: Navigating through ever-evolving regulations and certifications while ensuring compliance.

- Quality Control and Safety: Maintaining consistent standards and ensuring food safety amidst changing conditions.

- Inventory Management: Balancing inventory levels to reduce waste while meeting fluctuating consumer demands.

- Cost Control and Margin Pressure: Addressing cost fluctuations and maintaining competitive pricing in a dynamic market.

ERP Features for the Food & Beverage Industries

- Recipe and Formulation Management: Tools to manage recipes, formulas, and ingredient lists, ensuring consistency and compliance.

- Quality Management: Modules to track quality at every stage, conducting inspections and managing non-conformances.

- Supply Chain Visibility: Features allowing real-time visibility into the supply chain, from sourcing to distribution.

- Forecasting and Demand Planning: Tools to forecast demand accurately, optimizing inventory levels and production schedules.

- Compliance and Regulatory Support: Modules designed to meet industry-specific regulations and certifications.

Effectively Address Industry Challenges with ERP Features for Food and Beverage

ERP solutions tailored for the food industry offer specialized functionalities to tackle these challenges head-on. Solutions like Acumatica Cloud ERP provide comprehensive tools for supply chain management, compliance, quality control, and analytics, empowering businesses to streamline operations and adapt to market demands seamlessly.

Reasons Why Food Manufacturing ERP Systems are Required in Today’s Industry Climate

In today’s food industry climate, the necessity for Food Manufacturing ERP systems is underscored by the intricate demands and challenges businesses face. These systems are indispensable tools, offering a cohesive platform to manage multifaceted operations, address stringent regulatory requirements, ensure traceability, and maintain quality control throughout the production lifecycle.

The complexities of supply chain management, coupled with the need for real-time data insights, make ERP systems a linchpin for businesses striving to optimize inventory, streamline production, and navigate the intricacies of compliance in a constantly evolving landscape. With tailored features designed specifically for the food and beverage sector, ERP solutions like Acumatica Cloud ERP become indispensable allies, empowering businesses to adapt, innovate, and thrive in competitive and dynamic markets.

FAQs on ERP and Its Role in the Food Industry

How does ERP ensure food safety?

ERP systems enable traceability, ensuring that ingredients and products can be tracked through every stage, aiding in quick identification and response to safety issues or recalls.

Can ERP systems handle perishable inventory efficiently?

ERP systems with robust inventory management tools can manage perishable inventory by optimizing stock levels, minimizing wastage, and ensuring freshness.

What are the advantages of cloud-based ERP solutions in the food industry?

Cloud-based ERP solutions offer scalability, accessibility, and real-time data access, allowing seamless collaboration, remote operations, and cost-effective scalability.

In conclusion, ERP systems have become indispensable tools for food and beverage businesses, offering tailored solutions to mitigate challenges, enhance operational efficiency, and ensure compliance in a dynamic and demanding industry landscape. Acumatica Cloud ERP is an exemplar of a comprehensive solution empowering food businesses to thrive in the modern market.

Sangeetha brings 20 years of experience in Information Technology which includes Solution architecting, building micro services, research, and evaluation of business applications, integrating apps.