The machine tool manufacturing industry is expanding globally due to its highest demand in the market. Most of them are facing issues in quality, time delay, and waste. Therefore, to mitigate the shortcomings, a greater number of attractive quality tools have been established. There are several manufacturing companies all over the globe but the customer’s choice would be the one who relies on the quality of the product.

Today, most of the manufacturing industries have well known about the cost for replacement/repair of the product once it reaches the customer. Hence, they intend to reach the compliance standard to embrace the reputation and it can be achieved through focusing on significant factors such as factory performance, production process, supplier evaluation, a team mindset, identify the root cause, and so on.

Thus the product quality can be enriched either with quality control or quality assurance. Quality control is the approach where the finished products are scrutinized whereas in quality assurance the quality of the product is inspected at each production stage.

Every individual in the company should contribute to improving the quality of the product they produce. It’s not too difficult to solve the issues of the product at an early stage rather than finished products.

Let’s see the five activities that ensure the quality of the products

Recognize Your Product with product specifications

Detailed product specifications are required for success. The significant module of product quality is knowing what your product is. Hence, detailed product specifications are required that to identify how the product should come out. What the required product features are to meet the expectations. Thus, the product specifications comprise defect details with classifications. Also, elucidate the satisfactory quality levels and prospects for the supplier. Each defect is categorized as major, minor or critical.

Inspect potential/ Existing suppliers:

Inspection means checking/auditing the records of the organization related to accounts and infrastructure maintenance as well.

Hence, the process surveys and factory audits conduct to ensure that the existing suppliers deliver high-quality products. There are two types of general audits which include

Competence & Qualification of supplier – The auditors give feedback based on the operations, proficiencies, and qualifications of the suppliers. This helps to determine the feasibility of the supplier

Quality System & Process Control – The auditor measures the entire manufacturing process control system including the areas like quality control methods, management estimation, non-conforming materials, corrective action, production, and test equipment.

Product Testing

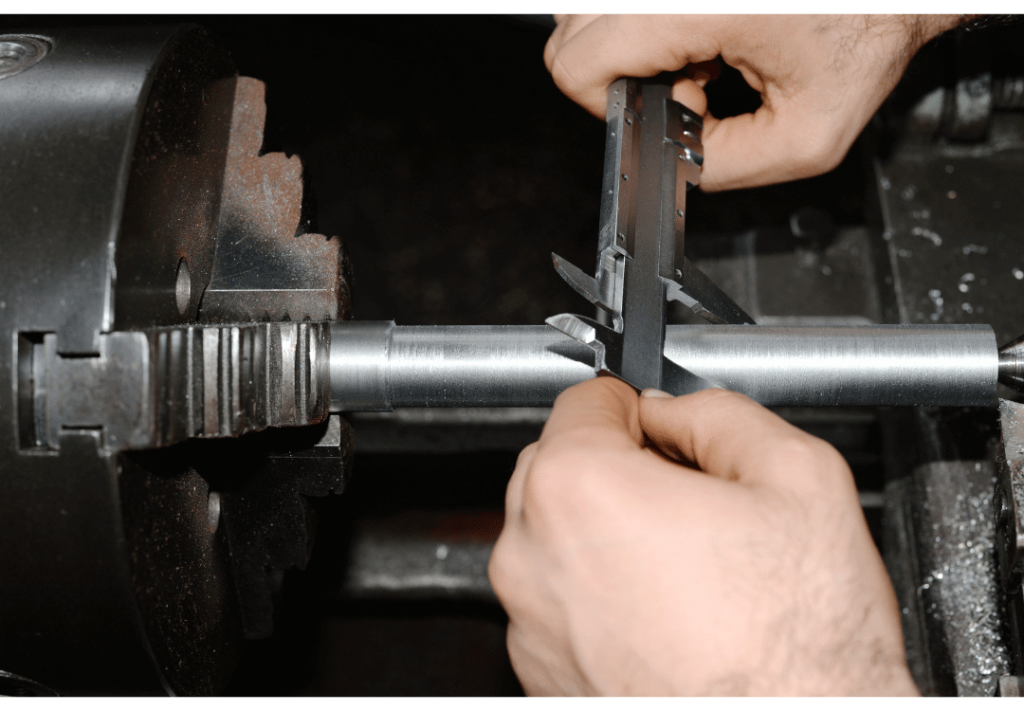

The quality of the product is ensured throughout the production process using appropriate industry-related standards for measuring product properties and evaluating performance. Thus, appropriate product testing can eliminate the costly delays and revise.

Audit each phase of Production

At each stage of the production cycle, the product’s quality has to be checked to reduce the risks and costs. Thus, this helps to identify the issues earlier to resolve them.

Unceasing Improvement

An incessant improvement initiative results in the following

Productivity gets enriched due to less time consuming on the reworking non-conformities

Service and cost are better

Quality standards To Transform Your Businesses

Quality standards are the foremost thing for Success. By meeting the quality standards, the company can attain profits and it also makes the company stand ahead of competitors. Companies use quality management tools to enhance the quality and meet the minimum requirements of the product quality. Total quality management, continuous quality management, and six sigma are the common compliance standard which companies use.

We can use specific tools that have specific functions for quality improvement methods. Most of the tools are free of charge and they act as a system. The significant tools to understanding the manufacturing processes better are the flow charts and process maps. Thus you can easily collect the data with the help of the tool named check sheets.

A histogram expresses the shape of the center and the spread of the data and the Pareto charts line up problems or root causes. The cause-and-effect diagram likely inspects the cause for particular problems. A Scatter diagram helps to recognize the relationship between the two variables. They can express if two variables that inter-relate but cannot find the source from this. Six Sigma metrics are important since it helps to find the process areas which needs improvement. The six-sigma metrics include Sigma level, the Rolled Throughput Yield (RTY), Defects per Unit (DPU), Defects per Million Opportunities (DPMO), The First Pass Yield (FPY)

Six Sigma

Six sigma is the methodology that comes from the TQM that reduces variations, evaluates the defects, and enhances the quality of products, services, and processes. To improve productivity, lean tracks its roots to the organization’s desire. Today most of the improvement ideas and viewpoints come from the evolving Lean and six sigma.

Thus, lean and six sigma eliminates the waste and excess cost and the customer experience also improves along with the business processes. Six sigma finds ways to solve the problems and dissatisfaction rather than responding to the issues. DMAIC is the process improvement methodology of the six sigma.

DMAIC specifies the six sigma business guidelines which are to Define, Measure, Analyse, Improve, and Control business performance. From large enterprises to small ones, have set up Six sigma strategies to increase the quality and save cost. Six sigma fulfills the organization’s goal primarily the quality through the process improvement with its outstanding strategies. Sig sigma continues to grow and industry leaders shape its dynamic strategies.

Streamlining the manufacturing process with ERP

Nowadays manufacturers are using vigorous ERP that is integrates QA to deliver high-quality products in manufacturing. Thus, relying on the ERP solutions throughout the production process delivers a high-quality product that yields more loyal customers. Moreover, ERP solutions offer a wide spectrum of business analytics that enlighten the effectiveness of various workflows, with production planning, inventory, and distribution.

Let’s discuss the quality assurance of Hyundai motors

We all know the Hyundai motors Isn’t it? the fact of being popular is their unmatched quality in manufacturing. Hyundai motors established its quality department in 2002 to improve the business standard with global customer satisfaction. In 2017, Hyundai set up a global quality center in India to benchmark the quality products, and its long-term strategy was put by the CEO of Hyundai Y K Koo. The key actions of that center would be creating quality products without any defect. Also, this center ensures top-level safety quality through a proactive customer-oriented management system.

Thus the manufacturing industry desires to deliver a product that meets the compliance standard. For that, they are implementing various quality tools some may work better but few don’t.

Are you searching for a Perfect manufacturing ERP tool?

Acumatica is the right place?

Acumatica offers enticing cloud manufacturing ERP software to the customers. The manufacturing edition of Acumatica supports several manufacturing practices including make to stock (MTS), make to order (MTO), engineer to order (ETO), configure to order (CTO), batch process, and more. Thus, with Acumatica, you can access it from anywhere and they can monitor the orders, material plans, and schedules and ensure quality in manufacturing. Furthermore, Acumatica provides a feature enriched ERP cloud manufacturing solution for your business.